Pesticide Use

Frequently Asked Questions

FAQ Sections

- General Pesticide Information and Understanding Pesticide Labels

- Worker Protection Standards (WPS)

- Medical Clearance and Fit Testing for Respirator Use

- Personal Protective Equipment (PPE)

- Spray Equipment

- Applying Pesticides (Organic and Conventional)

- Tank Mixing Pesticides with Other Products

General Pesticide Information and Understanding Pesticide Labels

Q. Is what I'm using a pesticide? What is a pesticide? And how can I better understand the pesticide label?

A. According to the EPA, the pesticide law defines a “pesticide” (with certain minor exceptions) as:

Watch the video below or click here to learn about pesticides (start to 9:34) and pesticide labels (9:35 to end). A Spanish version will be added soon.

A. According to the EPA, the pesticide law defines a “pesticide” (with certain minor exceptions) as:

- Any substance or mixture of substances intended for preventing, destroying, repelling, or mitigating any pest.

- Any substance or mixture of substances intended for use as a plant regulator, defoliant, or desiccant.

- Any nitrogen stabilizer.

- Makes a claim to prevent, kill, destroy, mitigate, remove, repel or any other similar action against any pest.

- Indirectly states or implies an action against a pest.

- Draws a comparison to a pesticide.

- Pictures a pest on the label.

Watch the video below or click here to learn about pesticides (start to 9:34) and pesticide labels (9:35 to end). A Spanish version will be added soon.

Q. Are certified organic products like Mycotrol ESO and Badge X2 pesticides?

A. Yes. The intended us products like Mycotrol ESO and Badge X2 are for preventing, destroying, repelling, or mitigating pests which include diseases. These certified organic products like many others with EPA registration numbers are considered pesticides.

A. Yes. The intended us products like Mycotrol ESO and Badge X2 are for preventing, destroying, repelling, or mitigating pests which include diseases. These certified organic products like many others with EPA registration numbers are considered pesticides.

Worker Protection Standards (WPS)

Q. Does WPS training apply to me?

A. You can take a simple survey to help you determine if WPS training applies to you. If WPS applies to you...

A. You can take a simple survey to help you determine if WPS training applies to you. If WPS applies to you...

- Annual training is required for workers and handlers.

- Worker training grace period is eliminated. Workers must be trained before they work in an area where a pesticide has been used or a restricted -entry interval has been in effect in the past 30 days.

- Trainers must be certified applicators or have completed an EPA-approved train-the-trainer program or be designated by the State or Tribal pesticide enforcement agency.

- Train-the-trainer programs and training materials must be EPA-approved.

- Employers must keep training records for 2 years and give a copy to workers and handlers upon request.

Q. Where can I learn more about protecting my workers and handlers who apply and work in areas where organic or conventional pesticides are used?

A. Visit the PERC website for resources on WPS and to download or purchase WPS materials and videos in various languages. You can also contact your local Hawaii Department of Agriculture's Pesticide Branch Education Section or your local Extension Agent if you have questions about WPS and pesticide use. Contact your local Extension Agent for educational events related to WPS and pesticide use.

A. Visit the PERC website for resources on WPS and to download or purchase WPS materials and videos in various languages. You can also contact your local Hawaii Department of Agriculture's Pesticide Branch Education Section or your local Extension Agent if you have questions about WPS and pesticide use. Contact your local Extension Agent for educational events related to WPS and pesticide use.

Medical Clearance and Fit Testing for Respirator Use

Q. I need to be medically cleared to wear a respirator for spraying. Where can I get this clearance done?

A. Inquire with your primary care physician (PCP) or a certified health care professional (CHCP) about an appointment for medical clearance to wear and use a respirator or, visit and online medical clearance site such as 3M.com. Retain and file your medical clearance.

If you are not medically cleared to wear a respirator, for your health and safety, you should not wear or use a respirator.

A. Inquire with your primary care physician (PCP) or a certified health care professional (CHCP) about an appointment for medical clearance to wear and use a respirator or, visit and online medical clearance site such as 3M.com. Retain and file your medical clearance.

If you are not medically cleared to wear a respirator, for your health and safety, you should not wear or use a respirator.

Q. Is there a form I need to take to my PCP to receive a medical evaluation and clearance to wear a respirator?

A. Contact your PCP or CHCP beforehand and ask if they are able to conduct a medical clearance for respirator use. If your PCP or CHCP has not done a medical clearance before, you might consider taking this OSHA Respirator Medical Evaluation Questionnaire (also in Spanish) AND this physician's evaluation form (English) or (Spanish) with you to your appointment. If your PCP or CHCP clears you to use a respirator, be sure to receive a completed and signed physician's evaluation form or document stating that you have been medically cleared. Retain and file your medical clearance.

OSHA requires that the content of the examination include, at least, the items covered in the questionnaire, but this is considered the minimum requirement for the medical evaluation. Any additional testing would be left to the discretion of the company's physician or other licensed healthcare provider.

A. Contact your PCP or CHCP beforehand and ask if they are able to conduct a medical clearance for respirator use. If your PCP or CHCP has not done a medical clearance before, you might consider taking this OSHA Respirator Medical Evaluation Questionnaire (also in Spanish) AND this physician's evaluation form (English) or (Spanish) with you to your appointment. If your PCP or CHCP clears you to use a respirator, be sure to receive a completed and signed physician's evaluation form or document stating that you have been medically cleared. Retain and file your medical clearance.

OSHA requires that the content of the examination include, at least, the items covered in the questionnaire, but this is considered the minimum requirement for the medical evaluation. Any additional testing would be left to the discretion of the company's physician or other licensed healthcare provider.

Q. How often do I need to get a medical clearance to use a respirator?

A. The respiratory protection standard requires an initial medical evaluation to determine the employee's ability to use a respirator before the employee is fit tested or required to use the respirator in the workplace. At a minimum the employer must provide additional evaluations if an employee shows signs or symptoms that are related to their ability to wear a respirator. There is not a specific annual requirement for medical evaluations in the standard. However, the physician or other licensed healthcare provider may prescribe annual tests to ensure employees' continued ability to wear a respirator.

A. The respiratory protection standard requires an initial medical evaluation to determine the employee's ability to use a respirator before the employee is fit tested or required to use the respirator in the workplace. At a minimum the employer must provide additional evaluations if an employee shows signs or symptoms that are related to their ability to wear a respirator. There is not a specific annual requirement for medical evaluations in the standard. However, the physician or other licensed healthcare provider may prescribe annual tests to ensure employees' continued ability to wear a respirator.

Q. Where can I get fitted for a respirator?

A. Obtain your medical clearance BEFORE attempting to schedule a respirator fit test.

Click here to find locations on Kauai, Oahu, Maui and the Big Island for respirator fit testing sites.

A. Obtain your medical clearance BEFORE attempting to schedule a respirator fit test.

Click here to find locations on Kauai, Oahu, Maui and the Big Island for respirator fit testing sites.

Q. How often do I need to be fit tested with my respirator?

A. Fit testing must be performed initially (before the employee is required to wear the respirator in the workplace) and must be repeated at least annually. Fit testing must also be conducted whenever respirator design or facial changes occur that could affect the proper fit of the respirator. Examples of conditions which would require additional fit testing of an employee include (but are not limited to) the use of a different size or make of respirator, weight loss, cosmetic surgery, facial scarring, the installation of dentures or absence of dentures that are normally worn by the individual.

A. Fit testing must be performed initially (before the employee is required to wear the respirator in the workplace) and must be repeated at least annually. Fit testing must also be conducted whenever respirator design or facial changes occur that could affect the proper fit of the respirator. Examples of conditions which would require additional fit testing of an employee include (but are not limited to) the use of a different size or make of respirator, weight loss, cosmetic surgery, facial scarring, the installation of dentures or absence of dentures that are normally worn by the individual.

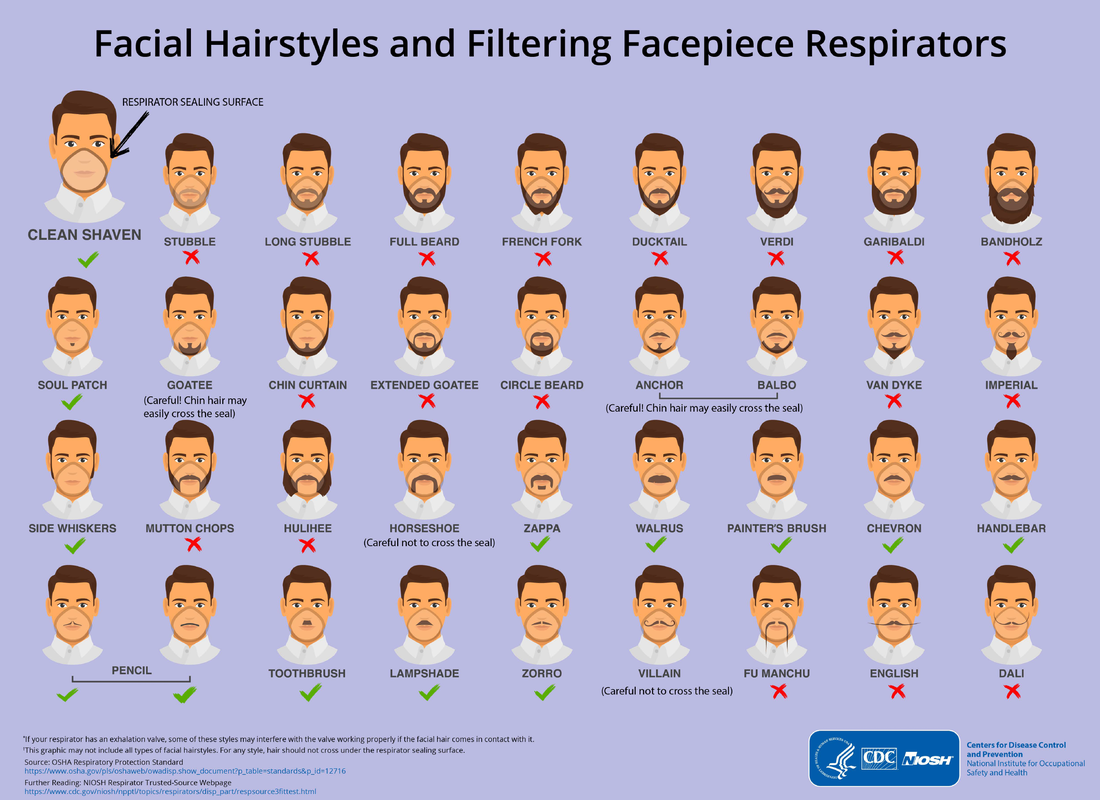

Q. Can I wear a respirator and still have facial hair?

A. Respirators must fit well on the face and/or head and maintain a tight seal for them to perform properly. Below are some examples of facial hairstyles with use of a filtering face piece respirator. Facial hairstyles may differ with use of a half or full facepiece or powered air purifying respirator.

A. Respirators must fit well on the face and/or head and maintain a tight seal for them to perform properly. Below are some examples of facial hairstyles with use of a filtering face piece respirator. Facial hairstyles may differ with use of a half or full facepiece or powered air purifying respirator.

- *If your respirator has an exhalation valve, some of these styles may interfere with the valve working properly if the facial hair comes in contact with it.

- †This graphic may not include all types of facial hairstyles. For any style, hair should not cross under the respirator sealing surface.

- Source: OSHA Respiratory Protection Standard (https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=standards&p_id=12716)

- Further Reading: NIOSH Respirator Trusted-Source Webpage (https://www.cdc.gov/niosh/npptl/topics/respirators/disp_part/respsource3fittest.html)

Personal Protective Equipment (PPE)

Q. What PPEs am I supposed to wear when spraying for Coffee Leaf Rust (CLR)?

A. The label is the law! When spraying pesticides, whether it be to control CLR, CBB, while spraying neem oil, BotaniGard ES or Mycotrol ESO, Pyganic, or other organic or conventional pesticides, you should first always read the product label directions before purchase and use. Sections on the label such as "Agricultural Use Requirements" will indicate the type of PPE required for handling, mixing, and application of the product. PPE requirements vary for each pesticide, so please read and follow the label.

A. The label is the law! When spraying pesticides, whether it be to control CLR, CBB, while spraying neem oil, BotaniGard ES or Mycotrol ESO, Pyganic, or other organic or conventional pesticides, you should first always read the product label directions before purchase and use. Sections on the label such as "Agricultural Use Requirements" will indicate the type of PPE required for handling, mixing, and application of the product. PPE requirements vary for each pesticide, so please read and follow the label.

Q. Where can I purchase coveralls, eye protection, gloves, and other PPEs?

A. Call or visit stores such as Ace Hardware, BEI, Farm and Garden, Garden Exchange, AirGas/GasPro, Farm Supply Cooperative, HPM, Nutrien, and Simplot to see if they have the proper PPEs available. You can search online and catalog sources as well. Check prices, shipping restrictions, and shipping costs before purchase.

There are various types and sizes of PPE. Be sure to read and follow the pesticide label first before purchasing and using any PPE. Be sure you are purchasing and using the proper PPE according to label directions.

Before use, double check that they are the correct PPEs according to the pesticide label. Inspect that the PPEs fit properly and are in working condition, and DO NOT use any PPE that is broken, torn, or otherwise non-functional.

A. Call or visit stores such as Ace Hardware, BEI, Farm and Garden, Garden Exchange, AirGas/GasPro, Farm Supply Cooperative, HPM, Nutrien, and Simplot to see if they have the proper PPEs available. You can search online and catalog sources as well. Check prices, shipping restrictions, and shipping costs before purchase.

There are various types and sizes of PPE. Be sure to read and follow the pesticide label first before purchasing and using any PPE. Be sure you are purchasing and using the proper PPE according to label directions.

Before use, double check that they are the correct PPEs according to the pesticide label. Inspect that the PPEs fit properly and are in working condition, and DO NOT use any PPE that is broken, torn, or otherwise non-functional.

Q. When I'm done spraying, what do I do with my PPEs?

A. This video shows an example of how to wash, handle, and remove PPEs after spraying that contain pesticide residues.

A. This video shows an example of how to wash, handle, and remove PPEs after spraying that contain pesticide residues.

Spray Equipment

Q. What is the best sprayer to use?

A. Selection of the best sprayer will be depend on your farm and financial situation, your spray applicator or worker's abilities, and the crop and pest.

Spray coverage is important for pest and disease control. Check, clean, and replace any worn, broken, and otherwise non-functional or poorly functioning sprayers, spray tanks, nozzles, hoses, gaskets, etc. Use and place water sensitive paper on all angles and heights of the plant to check for proper spray coverage on the leaves, berries, branches, etc.

Change or modify your wand, nozzle(s), pressure, walking speed, method of spraying, nozzle aperture, etc. to achieve proper coverage with current spray equipment. Or, purchase a sprayer that will give you better coverage. Before using new spray equipment, always test the sprayer, test for good coverage, and calibrate your sprayer.

A. Selection of the best sprayer will be depend on your farm and financial situation, your spray applicator or worker's abilities, and the crop and pest.

Spray coverage is important for pest and disease control. Check, clean, and replace any worn, broken, and otherwise non-functional or poorly functioning sprayers, spray tanks, nozzles, hoses, gaskets, etc. Use and place water sensitive paper on all angles and heights of the plant to check for proper spray coverage on the leaves, berries, branches, etc.

Change or modify your wand, nozzle(s), pressure, walking speed, method of spraying, nozzle aperture, etc. to achieve proper coverage with current spray equipment. Or, purchase a sprayer that will give you better coverage. Before using new spray equipment, always test the sprayer, test for good coverage, and calibrate your sprayer.

Q. Can I use the same sprayer and spray tank to apply different pesticides? Or do I need to purchase separate sprayers for each?

A. You can use the same spray equipment (tank, nozzle, and hose) to apply most pesticides. HOWEVER, it is recommended to use a different sprayer to apply herbicides.

When using the same spray equipment to apply fungicides, insecticides, and miticides, clean and wash the sprayer, tank, hose, and nozzle(s) well so no residues remain from the previous application. If you are unsure the spray equipment was cleaned prior, as a precaution, and wash before use as well.

Wear and use PPEs (according to the pesticide label) when cleaning spray equipment that has or could contain pesticides.

Directions for cleaning your coffee and orchard crops spray equipment*:

A. You can use the same spray equipment (tank, nozzle, and hose) to apply most pesticides. HOWEVER, it is recommended to use a different sprayer to apply herbicides.

When using the same spray equipment to apply fungicides, insecticides, and miticides, clean and wash the sprayer, tank, hose, and nozzle(s) well so no residues remain from the previous application. If you are unsure the spray equipment was cleaned prior, as a precaution, and wash before use as well.

Wear and use PPEs (according to the pesticide label) when cleaning spray equipment that has or could contain pesticides.

Directions for cleaning your coffee and orchard crops spray equipment*:

- After spraying, drain the sprayer (tank and line) immediately. Do not allow the spray solution to remain in the sprayer overnight prior to flushing.

- Flush the tank, hose, and nozzle(s) with clean water.

- Inspect and clean all strainers, screens, and filters.

- Prepare a cleaning solution with a commercial detergent or sprayer cleaner or ammonia according to the label directions.

- Take care to wash all parts of the tank, including the inside top surface. Start agitation in the sprayer and thoroughly recirculate the cleaning solution for at least 15 minutes. All visible deposits must be removed from the spraying system.

- Flush hoses, spray lines and nozzles for at least 1 minute with the cleaning solution.

- Remove nozzles, screens and strainers and clean separately in the cleaning solution after completing the above procedures.

- Drain pump, filter, and lines.

- Rinse the complete spraying system with clean water.

- Clean and wash off the outside of the entire sprayer to remove pesticide residues.

- All rinse water must be disposed of in compliance with local, state, and federal requirements.

Applying Pesticides (Organic and Conventional)

Q. What does it mean to calibrate my sprayer?

A. All sprayers should be calibrated to the applicator, field, and tree conditions. When using hand-held wand or backpack sprayers, each person applying pesticides will have a different method and speed at which they spray the trees. Spraying young, pruned, and sickly trees will have a lower water rate per acre than mature, tall, and densely foliaged trees. Calibrating your sprayer helps you determine water usage per acre and helps you to apply pesticides properly and at the label's recommended rate.

Spray to wetness and avoid runoff. Spraying too much pesticide wastes money by using more product than is needed. Applying too much pesticide and otherwise not following the label is also illegal. Violations can result in fines and jail time by both federal and state authorities, and crop or harvests can be confiscated and destroyed. The reputation of you and your farm could be damaged so future business is lost. Over-applying pesticides will unnecessarily expose you, your family, and your community to potentially toxic chemicals, and have environmental impacts, such as runoff that eventually reaches the ocean, or contamination of groundwater. Crop injury and phytotoxicity can also occur.

Spraying too little pesticide wastes money by spending time and product without getting the expected results. The grower will either need to re-treat or suffer from lower yields and quality from a damaged crop. An even bigger problem is that over time, misapplication can hasten the unwanted process of a pest developing resistance to the pesticide. Resistance will result in sprays not working even at the correct amount, so in addition to the cost of the wasted spraying, the pest still damages the crop so revenues are lower. Further, once pesticide resistance develops, fewer pesticides to control the problem are available and often are more costly. Spraying accurate amounts can help to slow the process by which pests develop resistance to pesticides.

A. All sprayers should be calibrated to the applicator, field, and tree conditions. When using hand-held wand or backpack sprayers, each person applying pesticides will have a different method and speed at which they spray the trees. Spraying young, pruned, and sickly trees will have a lower water rate per acre than mature, tall, and densely foliaged trees. Calibrating your sprayer helps you determine water usage per acre and helps you to apply pesticides properly and at the label's recommended rate.

Spray to wetness and avoid runoff. Spraying too much pesticide wastes money by using more product than is needed. Applying too much pesticide and otherwise not following the label is also illegal. Violations can result in fines and jail time by both federal and state authorities, and crop or harvests can be confiscated and destroyed. The reputation of you and your farm could be damaged so future business is lost. Over-applying pesticides will unnecessarily expose you, your family, and your community to potentially toxic chemicals, and have environmental impacts, such as runoff that eventually reaches the ocean, or contamination of groundwater. Crop injury and phytotoxicity can also occur.

Spraying too little pesticide wastes money by spending time and product without getting the expected results. The grower will either need to re-treat or suffer from lower yields and quality from a damaged crop. An even bigger problem is that over time, misapplication can hasten the unwanted process of a pest developing resistance to the pesticide. Resistance will result in sprays not working even at the correct amount, so in addition to the cost of the wasted spraying, the pest still damages the crop so revenues are lower. Further, once pesticide resistance develops, fewer pesticides to control the problem are available and often are more costly. Spraying accurate amounts can help to slow the process by which pests develop resistance to pesticides.

Q. How do I calibrate my sprayer?

A. Click here for instructions on how to calibrate your sprayer.

A. Click here for instructions on how to calibrate your sprayer.

Q. I have a 4 gallon tank. How much product do I add per gallon of water?

A. Ideally, a pesticide is applied at the concentration that kills the targeted pest(s) in the field, then quickly disappears from the environment. The proper pesticide rate and spray coverage is necessary for pesticides to be effective. Read and follow the label which will provide rates for the crop and/or pest targeted. When preparing pesticide solutions for application, you should know the following:

Click here to download a sprayer calibration publication and its associated Excel workbook for assistance with your calculations.

A. Ideally, a pesticide is applied at the concentration that kills the targeted pest(s) in the field, then quickly disappears from the environment. The proper pesticide rate and spray coverage is necessary for pesticides to be effective. Read and follow the label which will provide rates for the crop and/or pest targeted. When preparing pesticide solutions for application, you should know the following:

- Crop to be sprayed

- Your targeted pest

- Pesticide product to be applied

- Label rate

- Acres of crop or number of trees to be sprayed

- Water needed to spray (with good coverage) that acreage or number of trees

- Size of spray tank and total gallons of pesticide solution to be prepared in the tank

Click here to download a sprayer calibration publication and its associated Excel workbook for assistance with your calculations.

|

Q. What fungicides can I use to spray for CLR?

A. See the spraying for CLR suppression publication (English). This publication is also available in Spanish, Ilocano, and Tagalog. Table 1 provides a listing of organic and conventional pesticides that are legal to use and spray for CLR control on coffee in Hawaii. These products list CLR on the label. Effectiveness of each product may not be known for all products. Some costs per application are listed, but check with distributors for current product prices. If "Coffee" is not specifically named on the label, the product cannot be used on the coffee crop. It is a violation of the label to use a pesticide on coffee if the product is not approved for use by the Hawaii Department of Agriculture and if the label does not have "Coffee" listed as a crop. |

Q. Can I use products like Tilt, Sevin, or Quadris on my coffee trees?

A. No. These pesticides do not have "Coffee" listed on the label and NOT legal to use on coffee grown in Hawaii.

A. No. These pesticides do not have "Coffee" listed on the label and NOT legal to use on coffee grown in Hawaii.

Q. Can I leave the pesticide spray solution sitting over the weekend and use it on Monday?

A. Pesticides should, whenever possible, be mixed and sprayed as soon as possible. Avoid letting mixed spray solutions sit overnight or longer in the spray tank or mixing container, etc. Allowing pesticide solutions to sit can result in less active ingredient applied and poor pesticide performance. This in turn can cause pesticide resistance and the loss of effective pesticide products as well as increased costs and crop losses due to the use of less effective or ineffective spray applications and the need to reapply for pest and/or disease control. A sitting spray solution can also settle out and cause equipment clogging issues and damage.

The degradation of a pesticide can be measured in terms of its half life. For example, if a product has a half life of 4 hours, the amount of active ingredient is reduced to 50 percent in eight hours, to 25 percent in 12 hours, to 12.5 percent in 16 hours after mixing, etc. Eventually, the pesticide becomes virtually ineffective. Mix and use pesticides as soon as possible.

If you are short of spray solution or have left over spray solution after having calibrated your sprayer, try to figure out why this happened and re-calibrate your sprayer for better accuracy.

Always wash and thoroughly clean pesticide supplies, sprayers, hoses, nozzles, and equipment after the completion of a spray application to avoid contamination, crop injury, caking, clogging, and damage to the sprayer.

A. Pesticides should, whenever possible, be mixed and sprayed as soon as possible. Avoid letting mixed spray solutions sit overnight or longer in the spray tank or mixing container, etc. Allowing pesticide solutions to sit can result in less active ingredient applied and poor pesticide performance. This in turn can cause pesticide resistance and the loss of effective pesticide products as well as increased costs and crop losses due to the use of less effective or ineffective spray applications and the need to reapply for pest and/or disease control. A sitting spray solution can also settle out and cause equipment clogging issues and damage.

The degradation of a pesticide can be measured in terms of its half life. For example, if a product has a half life of 4 hours, the amount of active ingredient is reduced to 50 percent in eight hours, to 25 percent in 12 hours, to 12.5 percent in 16 hours after mixing, etc. Eventually, the pesticide becomes virtually ineffective. Mix and use pesticides as soon as possible.

If you are short of spray solution or have left over spray solution after having calibrated your sprayer, try to figure out why this happened and re-calibrate your sprayer for better accuracy.

Always wash and thoroughly clean pesticide supplies, sprayers, hoses, nozzles, and equipment after the completion of a spray application to avoid contamination, crop injury, caking, clogging, and damage to the sprayer.

Tank Mixing Pesticides with Other Products

Q. I want to reduce the number of times I need to spray. Can I tank mix different pesticides together? Can I tank mix pesticides with fertilizers?

A. Always read and follow product label directions before purchasing, mixing, and using (organic and conventional) pesticides. While the label may instruct you on the order of mixing products, what products not to tank mix, or that certain products are ok to mix together, you can also double check and inquire with the product manufacturer for tank mix compatibility for each product you are considering mixing.

A compatibility jar mix test can also help determine physical compatibility of the products. Here's a video (example) describing how to conduct a jar mix test. Jar tests do not determine efficacy of product compatibility. If a new combination of products is compatible with the jar test, also test the mix on a small area of the crop for pest and/or disease control efficacy. DO NOT test product mixes on your entire crop to avoid phytotoxicity, leaf, bud, flower, fruit or plant burning and damage, and crop losses.

Compatibility and pesticide efficacy can be affected by water pH. Check the pH of your water you will use to tank mix with prior to tank mixing. Read the product label for instructions on recommended water and/or final solution mixture pH. Adjust your water pH with an acidifying/buffering agent as necessary. Read about the effect of water pH on the stability of pesticides here.

Avoid using the same spray equipment to spray tree leaves, branches, and fruit, that was used to apply herbicides.

For specific tank mixing information pertaining to the following products, visit the website listed and/or contact the manufacturer of the pesticide.

A. Always read and follow product label directions before purchasing, mixing, and using (organic and conventional) pesticides. While the label may instruct you on the order of mixing products, what products not to tank mix, or that certain products are ok to mix together, you can also double check and inquire with the product manufacturer for tank mix compatibility for each product you are considering mixing.

A compatibility jar mix test can also help determine physical compatibility of the products. Here's a video (example) describing how to conduct a jar mix test. Jar tests do not determine efficacy of product compatibility. If a new combination of products is compatible with the jar test, also test the mix on a small area of the crop for pest and/or disease control efficacy. DO NOT test product mixes on your entire crop to avoid phytotoxicity, leaf, bud, flower, fruit or plant burning and damage, and crop losses.

Compatibility and pesticide efficacy can be affected by water pH. Check the pH of your water you will use to tank mix with prior to tank mixing. Read the product label for instructions on recommended water and/or final solution mixture pH. Adjust your water pH with an acidifying/buffering agent as necessary. Read about the effect of water pH on the stability of pesticides here.

Avoid using the same spray equipment to spray tree leaves, branches, and fruit, that was used to apply herbicides.

For specific tank mixing information pertaining to the following products, visit the website listed and/or contact the manufacturer of the pesticide.

Mention of trademark, proprietary product, or vendor does not constitute a guarantee or warranty of the product and does not imply its approval to the exclusion of other products or vendors that also may be suitable.

Information on this webpage is subject to change.

Information on this webpage is subject to change.

Contact website management if you require any assistance with the site or information provided.